The Role of Data in Industrial Decision-Making

Modern industrial enterprises increasingly rely on data-driven insights to navigate complex operational landscapes. From optimizing manufacturing processes to enhancing supply chain resilience, the strategic use of information has become fundamental to maintaining competitive advantage. Organizations across sectors are discovering that effective data utilization directly impacts productivity, innovation capacity, and long-term sustainability. Understanding how to harness this resource effectively represents a critical capability for industrial leaders seeking measurable improvements in performance and market positioning.

Industrial organizations today operate in environments where decisions must be both rapid and precise. The integration of data analytics into core operations has transformed how enterprises approach everything from daily workflow management to strategic planning. This shift reflects broader recognition that informed decision-making, grounded in empirical evidence rather than intuition alone, yields consistently better outcomes across operational dimensions.

How Does Data Drive Enterprise Strategy?

Strategic planning in industrial contexts now begins with comprehensive data collection and analysis. Organizations gather information from multiple sources including production systems, market trends, workforce performance metrics, and external economic indicators. This aggregated intelligence enables leadership teams to identify patterns, forecast challenges, and allocate resources with greater precision. Companies that establish robust data frameworks can respond more effectively to market shifts, adjust production schedules dynamically, and anticipate customer needs before competitors recognize emerging trends. The strategic advantage lies not merely in possessing data, but in developing organizational capabilities to interpret and act upon insights quickly.

What Role Does Technology Play in Operations?

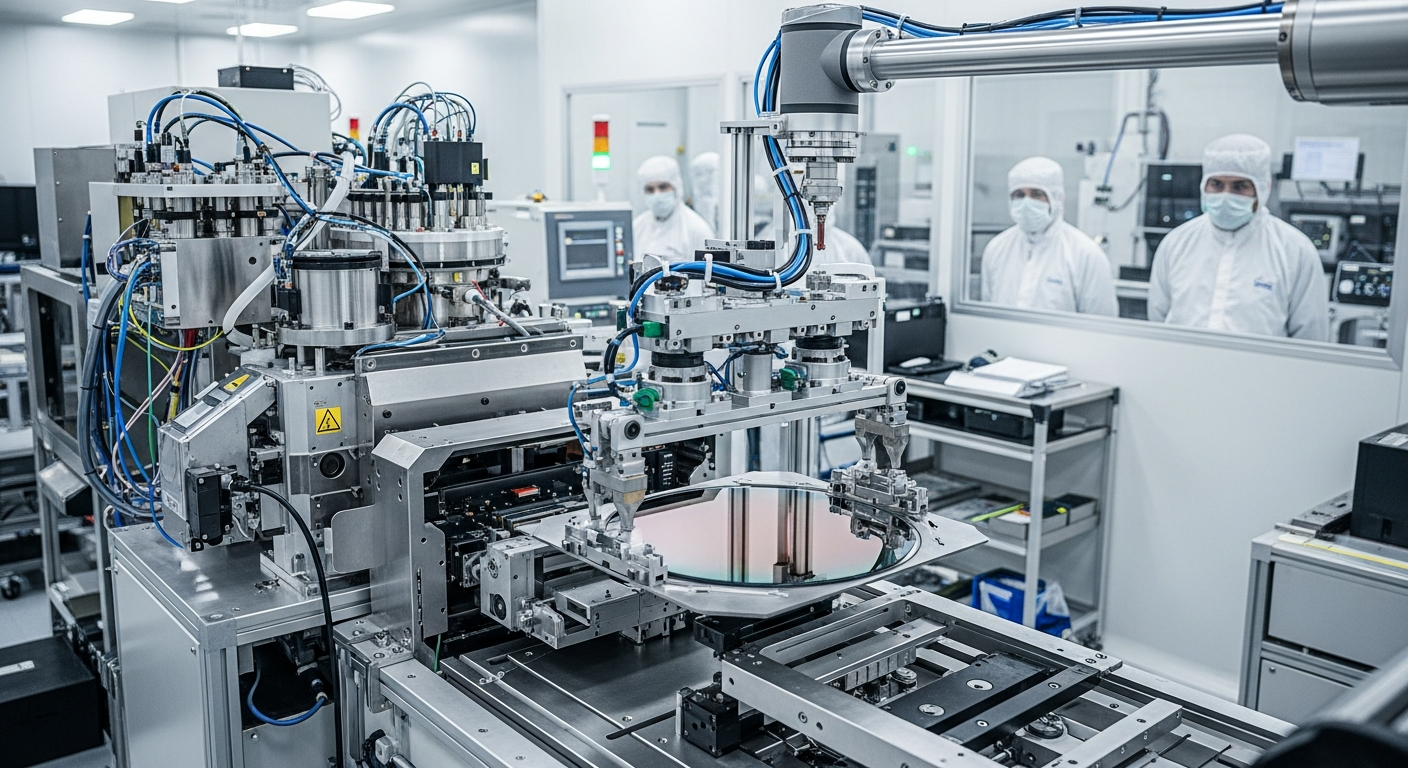

Digital transformation has fundamentally altered operational management across industrial sectors. Advanced sensors, Internet of Things devices, and integrated software platforms generate continuous streams of operational data. Manufacturing facilities utilize real-time monitoring systems to track equipment performance, identify maintenance needs before failures occur, and optimize energy consumption patterns. Automation technologies powered by data analytics reduce human error, accelerate production cycles, and improve quality control consistency. These technological implementations require significant initial investment but typically deliver measurable returns through reduced downtime, lower operational costs, and enhanced output quality. Organizations must carefully evaluate which technologies align with their specific operational challenges and growth objectives.

How Can Manufacturing Improve Efficiency Through Data?

Production efficiency gains represent one of the most tangible benefits of data-driven decision-making. Detailed analysis of manufacturing processes reveals bottlenecks, waste patterns, and opportunities for optimization that remain invisible through traditional observation methods. By tracking cycle times, material usage rates, and quality metrics across production lines, managers can implement targeted improvements that compound over time. Predictive analytics help forecast demand fluctuations, enabling more accurate inventory management and reducing carrying costs. Machine learning algorithms identify optimal parameter settings for complex manufacturing equipment, often discovering efficiency gains that exceed human-designed configurations. Continuous monitoring and iterative refinement based on performance data create self-improving systems that steadily enhance productivity.

What Impact Does Data Have on Supply Chain Resilience?

Supply chain management has become increasingly complex as global networks expand and just-in-time delivery models proliferate. Data analytics provides critical visibility across these extended networks, allowing organizations to monitor supplier performance, track shipments in real-time, and identify potential disruptions before they cascade into major problems. Historical data analysis reveals vulnerabilities in supply networks, informing decisions about supplier diversification and inventory buffer strategies. During periods of market volatility or unexpected disruptions, organizations with sophisticated supply chain analytics can pivot more quickly, identifying alternative suppliers or adjusting production schedules to minimize impact. This resilience translates directly into competitive advantage, as companies maintain delivery commitments while competitors struggle with unexpected shortages or delays.

How Does Data Support Workforce Development and Productivity?

Human capital management benefits significantly from data-driven approaches. Organizations track performance metrics, skill development progress, and workforce utilization patterns to optimize team composition and training investments. Analytics reveal which training programs deliver measurable productivity improvements and which represent poor return on investment. Workforce planning tools use historical data and predictive models to forecast staffing needs, reducing both understaffing crises and costly overstaffing situations. Safety data analysis identifies high-risk activities and conditions, enabling targeted interventions that reduce workplace injuries and associated costs. Employee engagement metrics help management understand organizational health and address morale issues before they impact retention or productivity. The systematic application of data to workforce management creates more efficient, safer, and more satisfying work environments.

What Frameworks Support Innovation and Sustainable Growth?

Long-term industrial success requires balancing immediate operational demands with strategic innovation and sustainability objectives. Data frameworks that integrate environmental impact metrics, resource consumption patterns, and innovation pipeline performance provide holistic views of organizational health. Companies increasingly track carbon emissions, waste generation, and energy efficiency alongside traditional financial metrics, recognizing that sustainability directly affects regulatory compliance, brand reputation, and operational costs. Innovation metrics help organizations assess research and development effectiveness, identifying which projects warrant continued investment and which should be discontinued. Market data analysis informs product development decisions, ensuring new offerings align with customer needs and competitive dynamics. Organizations that establish comprehensive measurement frameworks connecting operations, innovation, and sustainability position themselves for resilient growth across economic cycles and evolving regulatory landscapes.

The transformation of industrial decision-making through data represents an ongoing evolution rather than a completed transition. Organizations at various stages of this journey must continuously refine their capabilities, invest in appropriate technologies, and develop workforce competencies to extract maximum value from available information. Those that successfully integrate data-driven approaches across strategic planning, operational management, and innovation processes gain measurable advantages in efficiency, resilience, and market competitiveness. As data generation continues accelerating and analytical tools become more sophisticated, the gap between data-proficient organizations and those relying on traditional methods will likely widen, making this capability increasingly essential for industrial success.