Understanding Semiconductor Manufacturing Advancements

Semiconductor manufacturing stands as a cornerstone of modern technology, driving the evolution of everything from personal computing devices to advanced communication networks. The continuous pursuit of miniaturization, efficiency, and power in these tiny electronic components has led to significant breakthroughs. These advancements are not merely incremental; they represent fundamental shifts in how integrated circuits are designed, fabricated, and integrated into the broader digital ecosystem, impacting industries worldwide.

Examining Core Advancements in Semiconductor Technology

The landscape of semiconductor technology is characterized by relentless innovation. Recent years have seen substantial progress in materials science, lithography techniques, and architectural design, collectively pushing the boundaries of what is possible. Innovations in extreme ultraviolet (EUV) lithography, for instance, have enabled the production of much smaller features on silicon wafers, leading to denser and more powerful circuits. Beyond silicon, research into novel materials like gallium nitride (GaN) and silicon carbide (SiC) is opening new avenues for high-power and high-frequency applications, crucial for modern electronics and power management. These developments are foundational to the creation of more sophisticated components and integrated systems.

Impact of Innovations on Modern Computing and Devices

The continuous evolution in semiconductor manufacturing directly translates into enhanced capabilities for computing and various digital devices. Smaller transistors mean more processing power can be packed into the same physical space, leading to faster and more energy-efficient processors. This directly benefits everything from smartphones and laptops to complex data center servers, enabling more intricate software applications and robust hardware performance. The advancements facilitate the development of more sophisticated gadgets and devices, offering users improved experiences and opening doors for entirely new product categories that rely on powerful, compact electronics. Improved memory and storage components are also a direct result, allowing for faster data access and higher capacities, which are critical for today’s data-intensive world.

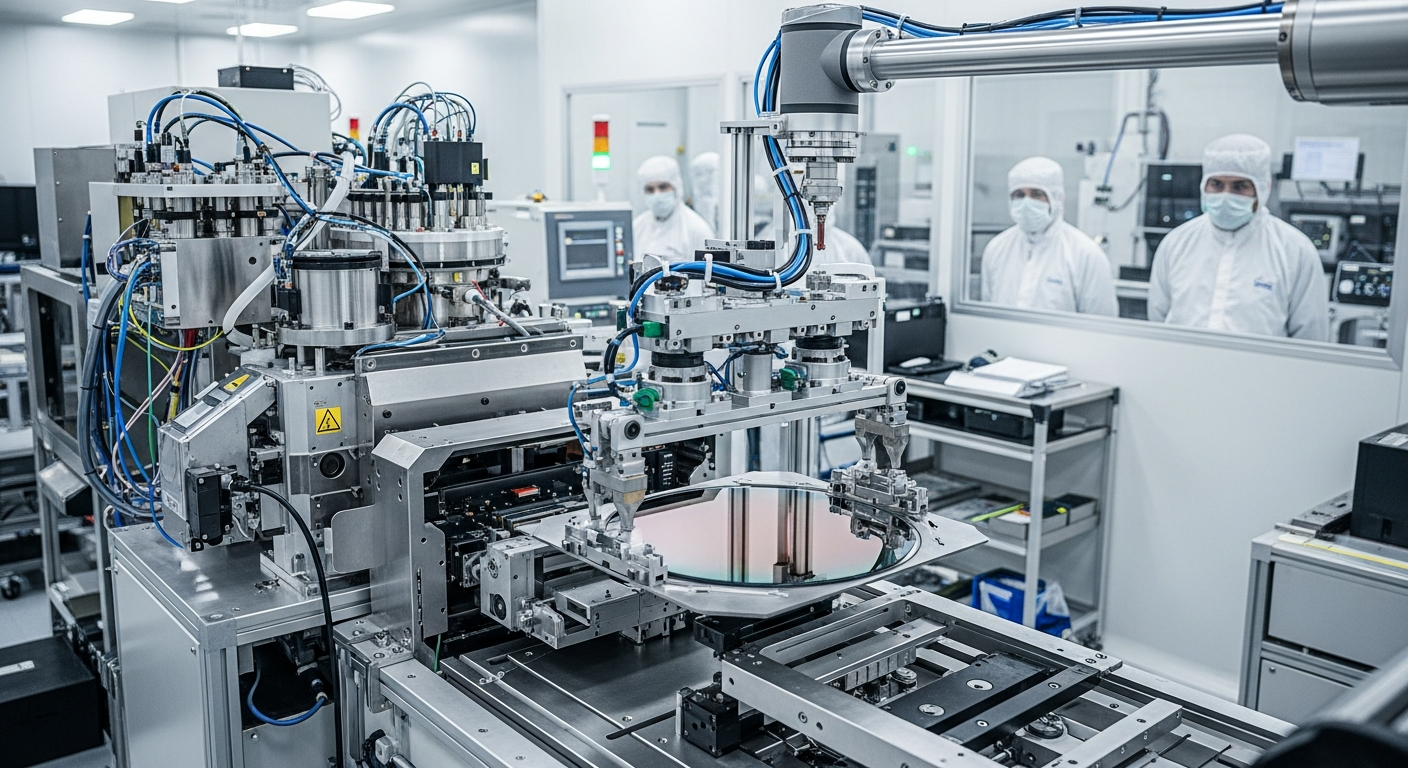

The Role of Automation and Robotics in Production

The intricate nature of semiconductor fabrication demands an exceptionally precise and controlled environment. Automation and robotics play a pivotal role in achieving the required levels of accuracy and efficiency. Advanced robotic systems handle delicate silicon wafers throughout the manufacturing process, minimizing human contact and preventing contamination, which is critical for yield rates. Automated guided vehicles (AGVs) transport materials between different processing stations in cleanrooms, ensuring a seamless and highly efficient workflow. Furthermore, artificial intelligence and machine learning algorithms are increasingly being used to monitor production lines, predict equipment failures, and optimize manufacturing parameters, contributing to higher quality and reduced costs in the complex production of microchips and other components.

Evolution of Processing Capabilities and Networking Components

The drive for higher processing capabilities is a constant in the semiconductor industry. Modern chips feature multi-core architectures, specialized accelerators for AI tasks, and advanced interconnect technologies that allow different parts of a chip to communicate more efficiently. This evolution is vital for handling the increasing demands of data processing in diverse applications, from high-performance computing to edge devices. Concurrently, advancements in semiconductor manufacturing directly enhance networking components. Faster and more reliable communication chips are essential for the expansion of 5G networks, data centers, and the broader internet of things (IoT). These improvements enable quicker data transmission, lower latency, and greater bandwidth, which are fundamental to a globally interconnected digital infrastructure.

Future Trends in Semiconductor Manufacturing for Digital Electronics

Looking ahead, semiconductor manufacturing is poised for further transformative changes, particularly in the realm of digital electronics. Research and development efforts are concentrated on several key areas, including advanced packaging technologies that allow for the integration of different types of chips (e.g., CPU, GPU, memory) into a single, compact unit, improving performance and power efficiency. The exploration of quantum computing architectures and neuromorphic chips, designed to mimic the human brain, represents long-term innovation pathways. These future trends aim to address the growing computational demands of artificial intelligence, big data analytics, and other emerging technologies, ensuring that the digital world continues to advance with ever more capable and efficient hardware.

Semiconductor manufacturing advancements are a continuous cycle of innovation, driving the capabilities of nearly every piece of modern electronic equipment. From the fundamental materials and intricate fabrication processes to the sophisticated automation involved, each step contributes to the creation of more powerful, efficient, and versatile components. These developments underpin the ongoing evolution of computing, communication, and digital technologies, shaping the future of how we interact with the world and process information.